The following text is by Adolph E. Peschke as presented in the 1998 printing of the 1993 edition of the Pioneering Merit Badge Pamphlet:

KEY FACTORS TO CONSIDER

There are several important factors to consider when selecting the kind and size of rope to use in pioneering and camping activities. Three of the most important factors to consider are the strength in both the working load and breaking point of the rope, the stretch factor of the rope, and how easily the rope handles.

There are several important factors to consider when selecting the kind and size of rope to use in pioneering and camping activities. Three of the most important factors to consider are the strength in both the working load and breaking point of the rope, the stretch factor of the rope, and how easily the rope handles.

Some other considerations are the rope’s resistance to mildew, its ability to stand up to repeated wetting and drying, and whether or not it retains kinks from knots after having been under a hard strain, making it difficult to use a second time.

Cost is always an important factor to consider when equipping a pioneering kit. Factors that affect cost are quality, grade, packaged cut length, and source of supply. Scout units can usually buy rope from wholesale suppliers if it’s purchased in standard package lengths. Manila rope in 1/4″ diameter comes in a standard 1200′ coil, while larger diameters come in 600′ coils. Most other types of rope come in 600′ spools as a standard package. Shorter lengths are available from retail suppliers.

ADDITIONAL FACTORS

- Since all rope types and sizes come in different grades of quality, which can relate to the strength, it is best to refer to the manufacturer’s specifications that appear on the package. It is a good idea to keep the package for future reference.

- Braided rope is about 10 percent stronger than twisted rope of the same diameter and type.

- Even the best knots can reduce rope strength 20 percent.

- Overhand knots reduce strength 50 percent.

- Polypropylene ropes lose strength when exposed to sunlight for extended periods of time.

- Nylon rope is 20 percent elastic and stretches to add 20 percent to its original length.

- The working load strength of most types of rope is up to 20 percent of its breaking strength. If available, go to the manufacturer’s specifications to determine the safe working load.

- Good care and storage will prolong useful life.

- Frequent inspections and discarding questionable rope is essential to ensure safe working equipment.

TYPES OF ROPE

Manila. Pure manila rope is by far the best all-around rope. It is easy to handle, has good strength-to-size ratio, and does not have an objectionable stretch factor. It handles well in three important pioneering areas: knot tying, lashing, and in using a block and tackle.

Manila rope can be spliced easily and withstands repeated wetting and drying cycles, making it suitable for boat and marine use, as well as many camping and pioneering applications. Manila rope should provide the bulk of the rope needed for your troop’s pioneering kit. (Its cost is mid-range.) Properly cared for it will give good service for quite a few years.

Polypropylene. Rope made of this man-made plastic fiber should be considered for pioneering activities because it is lightweight and its strength-to-size ratio is good. Size for size it is twice as strong as manila rope, but has a little higher stretch factor. Its strength makes it suitable for anchor strops and for any application involving heavy strain.

Polypropylene does stretch under a hard pull, but should not pose a problem if taken into consideration beforehand. A hard pull will result in kinking with some knots. Polypropylene resists mildew and will float, making it a good rope for waterfront activities and in wet conditions.

It is easy to splice in a twisted three-strand form. Because it is somewhat slippery, four tucks should be made instead of the usual three tucks. Cut ends should be both melted back and whipped with a good flax cord.

A disadvantage of polypropylene is that long exposure to sunlight has a weakening effect on the fibers. But, all things considered it is is worth including in your pioneering supplies.

Nylon. Nylon is commonly available in both braided nylon and twisted forms. Both forms come in a loose braid or twist and in a hard solid braid or twist. The loose braid or twist is not as strong and its fibers can easily get caught on bark, which can be bothersome. The hard twist or braid costs more, but is well worth its price.

Nylon rope is strong for its size, It is two an a half times stronger than the same size manila rope but loses some of its strength when wet. The three-strand twisted form of nylon can be spliced, but, as with polypropylene rope, it’s best to make four tucks instead of the usual three tucks and the cut ends should be both melted back and whipped to prevent raveling.

The most prevalent disadvantage of nylon rope is that it has a 20 percent stretch factor. But in cases where the stretch factor can be taken up with adjustment to the strain on the line, its strength can be an advantage. Nylon rope also has a tendency to slip when a hard pull is put on some knots. Because of these two factors, it is almost useless as a lashing rope.

All things considered, there is a place for both twisted and braided nylon rope in the solid, not loose, form.

Polyester. This man-made fiber rope is usually seen in the braided form. It handles well, is strong, and its stretch factor is less than nylon. It costs more than manila or nylon, but some sizes and lengths could be used in pioneering activities on a selected basis. A 6′ length of 1/4″-diameter polyester rope makes an excellent rope for practicing knot tying and pioneering games.

Polyethylene. This is the cheapest of man-made fiber ropes. It is most often seen in braided form and has a distinctive shine. Don’t let the low cost lure you into buying any quantity of polyethylene for pioneering or camp use. It is not suited for either knot tying or lashing because it holds kinks after being under a strain. (Since it floats it does have some very limited use at he waterfront for ski ropes or other waterfront activities).

Sisal. Sisal rope has much the same appearance as manila rope, but it is quite inferior in strength and does not handle well when used for lashing or knot tying. When sisal rope that is tied into a knot or lashing gets wet and then dries, it becomes useless because of the kinks that remain.

Even though it costs less. it is not cost effective because it breaks down quickly during use and when it gets wet. It might offer limited use in cases where expendable, but overall the cost is high when compared to other types of rope that can be used again and again.

Cotton. Cotton rope in both twisted and braided forms is outclassed in strength by other types and today there is little use for it in pioneering and camping.

Binder twine. Binder twine is made from loosely twisted jute fibers that are treated with oil during manufacturing. Its principle use today is for tying up bales of hay as the baling machine compresses the hay.

Binder twine is readily available in varying quantities at hardware and farm supply stores. Its low cost makes it a throwaway item after use. But don’t be too quick to toss it in the trash—a balled up handful of discarded twine makes a very good fire starter in camp.

Here are some uses for binder twine:

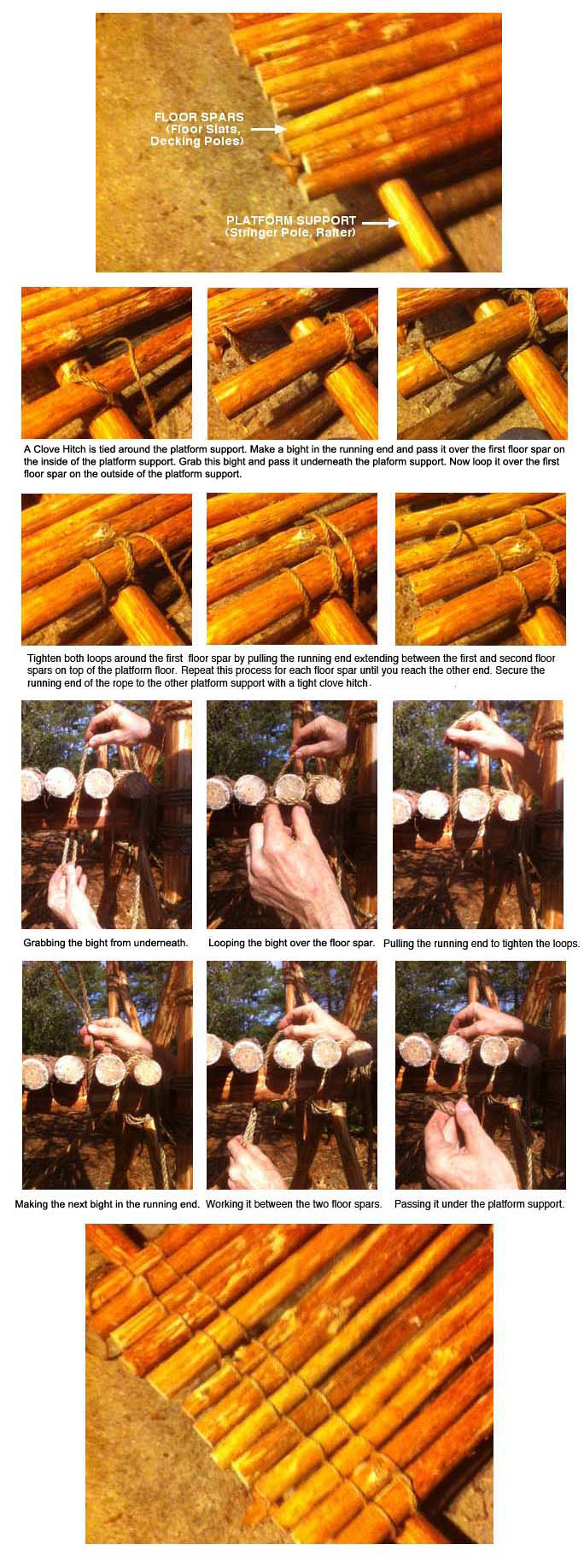

- When pioneering projects or camp gadgets call for the use of saplings less than 2″ in diameter, binder twine can be used for lashing. (Do not use binder twine as a replacement for 1/4″ rope in general pioneering use or lashings.)

- Use binder twine to make a simple strop lashing with six or eight wraps and a square knot.

- Use binder twine to hold the cross spars of a light bridge walkway in place.

- Two strands of binder twine quickly twisted together will equal a light cord. Use binder twine for the back stays of anchor stakes.

- Use binder twine to outline the ax yard for safety.

- Use binder twine for the construction of pioneering camp gadgets.